Rotary drum brewers grains dryer

Relying on the powerful technical strength, we can customized calculate and design the equipments according to the detailed material condition and requirements from customers. Make sure the equipments most suitable to the users.

Relying on the powerful technical strength, we can customized calculate and design the equipments according to the detailed material condition and requirements from customers. Make sure the equipments most suitable to the users.

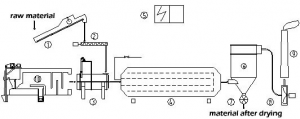

Structure:

It consists of six systems and 20 units of equipments, that are closed to run the whole process automatically.

1. feeding system

2. heating system (fuel can be coal, gas, oil, biomass)

3. drying system

4. collecting system

5. cooling system

6. control system

Model and Parameters

| Model | CMRD-9 | CMRD -18 | CMRD -36 | CMRD -54 | ||||||||

| Initial moisture content | 70% | 60% | 55% | 70% | 60% | 55% | 70% | 60% | 55% | 70% | 60% | 55% |

| Final moisture content | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% | 10% |

| Water removal( kg/h) | 900 | 1800 | 3600 | 5400 | ||||||||

| Output Capacity(kg/h) | 450 | 720 | 900 | 900 | 1440 | 1800 | 1800 | 2880 | 3600 | 2700 | 4320 | 5400 |

| Coal consumption( kg/t) | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 | 400 | 250 | 200 |

| Power consumption(kwh) | 27 | 40.8 | 60 | 76.8 | ||||||||

| Installed capacity(kw) | 45 | 68 | 100 | 128 | ||||||||

| Whole set of equipments floor area: L(m) × W(m) × H(m) | 24 × 8 × 7 | 28 × 9 × 8 | 32 × 10 × 9 | 36 × 12 × 10 | ||||||||

Feature:

1. Fast drying, great intensity

The drying drum is a three-pass structure, with special lifting flights inside the drum. As the drum rotates, the product is repeatedly showed into the dryer hot gas. Coefficient of thermal capacity can reach 300~500cal/m2hco. It is the new technology of high temperature and fast drying with large heat transfer coefficient. It can produce up to 8 tons per hour of dry materials.

2. Energy conservation, low cost

This is a full automatic control equipment, which operates continuously. It has high thermal efficiency, using an advanced state like superheated steam. It saves 15% ~ 20% of the energy than the usual drying system. Four kinds of fuels can serve the hot-air furnace: oil, gas, coal and biomass. Coal fired dryer needs consumption of 150Kg ~ 500Kg coal to produce each ton of dry material.

3. Good drying quality

It adopts a speed adjusting feeder that has a leveler to realize uniform loading. Oil and gas fired dryer adopt the combustion engine with proportional controller; coal fired dryer uses fuzzy controller. The humidity can be regulated automatically. Therefore, it not only ensures the quality of drying, but also prevents the loss of the material’s active ingredients.

4. Safe production, good working environment

Pipelines are with explosion releasing apparatus and automatic fire extinguishing system, so production is safe and reliable. The whole system works under negative pressure, without dust and noise, creating a good working environment.

Applications:

Charcoal, coal briquette, orange peel, baggasse, Bentonite, antibiotic bacterial residue, cow dung, brewers grains, distillers grains, spent grains, beer waste, alfalfa, marigold, ginkgo leaf, barley malt, chemical industry, seed, straw, Marc, sawdust, sludge, herbal, etc.